Flange Types

Weld Neck

This flange is circumferentially welded into the system at its neck, which means that the integrity of the buttwelded area can be easily examined by radiography. The bores of both pipe and flange match, which reduces turbulence and erosion inside the pipeline. The weld neck is therefore favoured in critical applications.

Slip-on

This flange is slipped over the pipe and then fillet welded.

Slip-on flanges are easy to use in fabricated applications.

Blind

This flange is used to blank off pipelines, valves and pumps.

It can also be used as an inspection cover. It is sometimes referred to as a blanking flange.

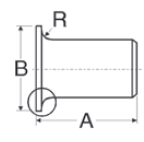

Socket Weld

This flange is counter bored to accept the pipe before being fillet welded. The bore of the pipe and flange are both the same therefore giving good flow characteristics.

Threaded

This flange is referred to as either threaded or screwed. It is used to connect other threaded components in low pressure, non-critical applications. No welding is required.

Lap Joint

These flanges are always used with either a stub end or taft which is buttwelded to the pipe with the flange loose behind it. This means the stub end or taft always makes the face. The lap joint is favoured in low-pressure applications because it is easily assembled and aligned.

Ring Type Joint

This is a method of ensuring leak proof flange connection at high pressures. A metal ring is compressed into a hexagonal groove on the face of the flange to make the seal. This jointing method can be employed on Weld Neck, Slip-on and Blind Flanges.